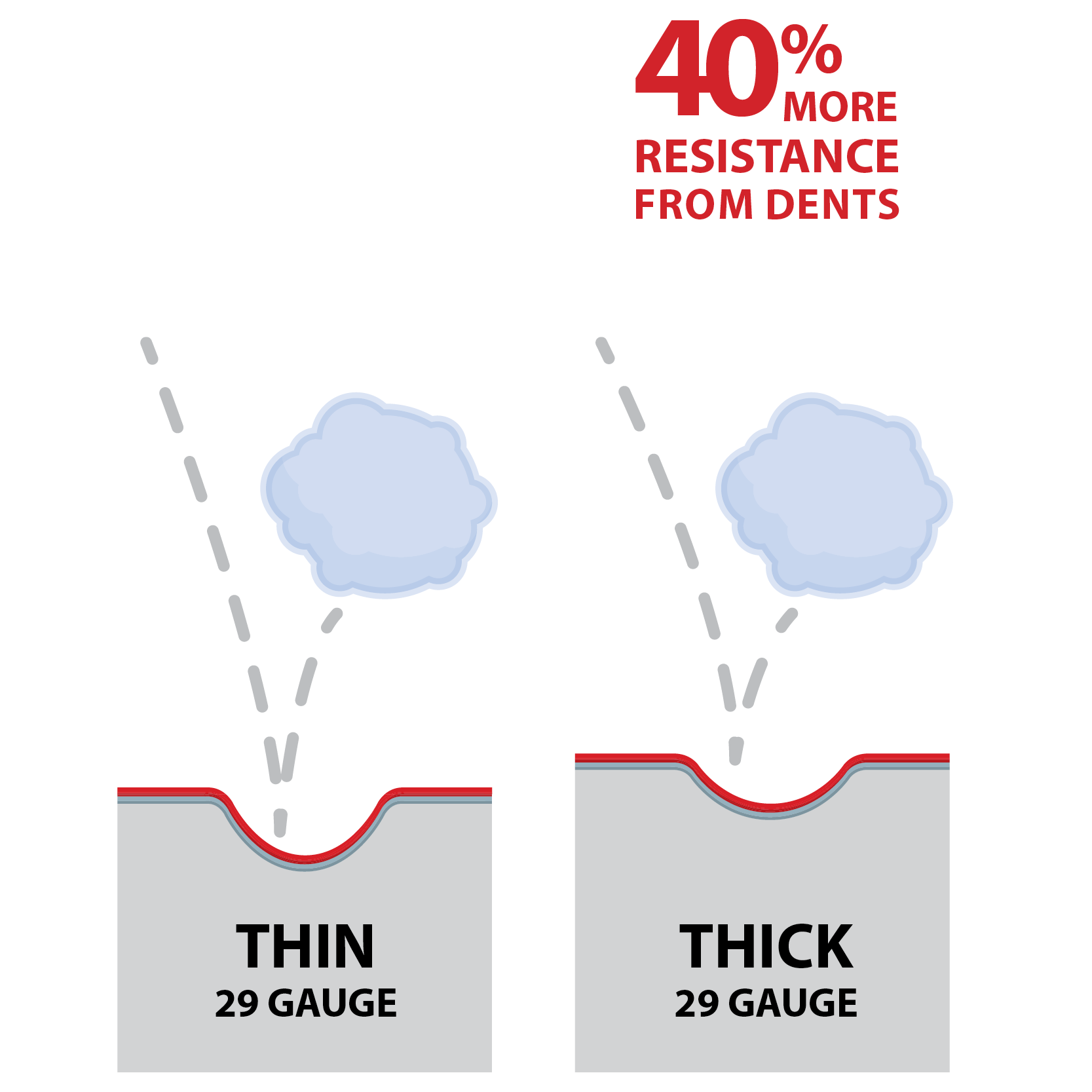

Some people may believe that thicker is always better but whether it needs that added strength actually depends on the type of building construction as well as its location.

29 gauge metal roofing reviews.

Here are a few details on the fit and finish of inexpensive metal roofing.

Despite this thicker lighter gauge panels can make sense for buildings in hail prone areas but not because of structural integrity.

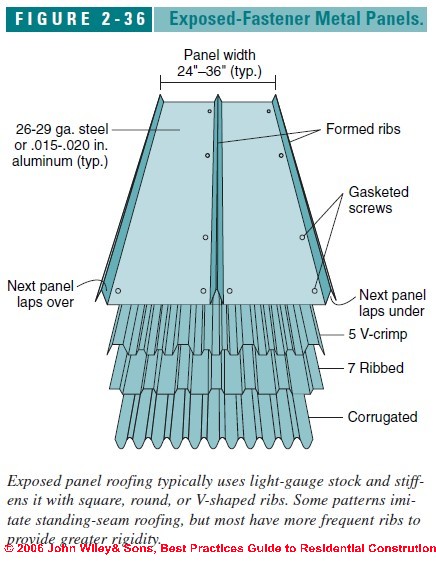

The standard gauges for residential roofs are 22 through 29.

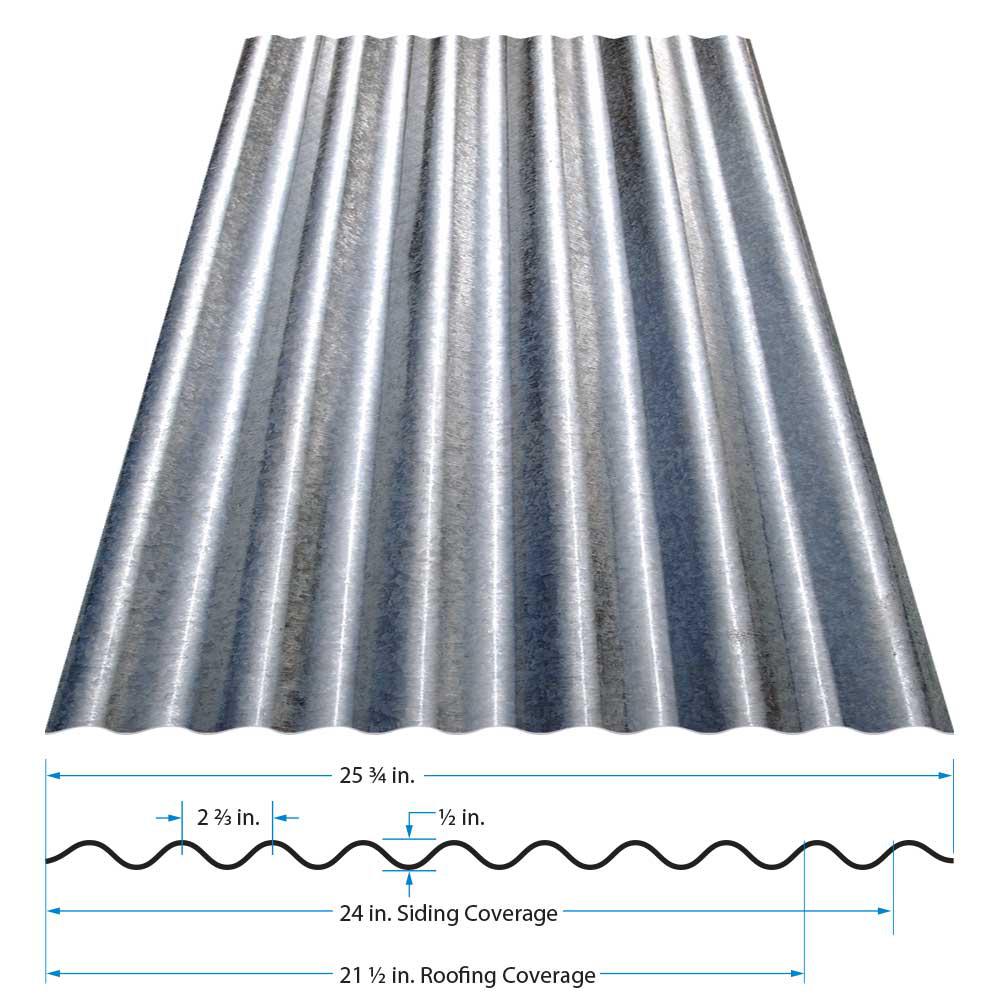

For example standard 29 gauge steel roofing made in long panels is about 0 36 millimeters thick and the 26 gauge version is slightly thicker at 0 48 millimeters.

22 is the thickest gauge while 29 is the thinnest.

Thicker metal sheets such as a 20 gauge spiral duct automotive body panels or furnace jackets are not a problem as well.

A 29 gauge metal panel can have the same impact resistance rating from underwriters laboratory ul as a 26 gauge panel.

These numbers refer to the decimal thickness of the steel and they have a range.

Coverage for roofing or siding.

Hence it can capably cut through 18 gauge mild and galvanized steel.

29 gauge thickness recommended for roof slopes of 3 12 pitch or greater.

Likewise it does a good job of cutting sheet metals both ferrous and non ferrous steel mesh metal roofing and building panels.

Sm rib panels are a good choice for the environment.

The gauge of a metal roof refers to its thickness and the higher the gauge the thinner the metal.

26 gauge vs 29 gauge metal.

Other factors are at play when it comes to metal roofing durability.

After a long service life they are still 100 recyclable.

Gauges for residential buildings.

The advantage of thicker metal panels in this case is that they are less prone to denting.

Metal roofing gauge sizes.

For reference a can of soda is usually 37 gauge while the thickness of the hood of a car is 20 gauge.